Tandemloc was founded in 1984, but our roots go back even further than that- all the way back to the 1950's when Tandemloc's founder, Mike DiMartino Sr., entered the industry as a draftsman at a company that manufactured cargo tie-downs as the container industry was born.

In 1973, after much success designing securing devices, Mike Sr. set out on his own, opening a new company offering their own line of container securing devices and some container lifting products.

Along the way, the military needed specialized securing devices, which led to the design of the “Tandemloc Connector” which would later be the namesake of Tandemloc Inc. after Mike’s original company closed after a decade run.

In 1984, Tandemloc was born in the basement of DiMartino Sr’s. house in Suffolk County, NY, alongside his son John DiMartino Jr.

The company spent its first decade building its business and establishing a reputation for designing some of the markets finest equipment for specialized container applications, like the “Tandemloc Connector”. But New York’s high manufacturing costs and demanding regulatory and red tape processes changed the trajectory for Tandemloc and the family.

In 1992, while John DiMartino Jr., his wife Sue and their young children were visiting the coast of NC, they met a realtor who offered a 5,000 square foot building in Havelock, NC for an unbelievable $1 a month for the first two years of the lease. Of course, they accepted and purchased the building when the lease expired, and Tandemloc has been headquartered in Havelock ever since.

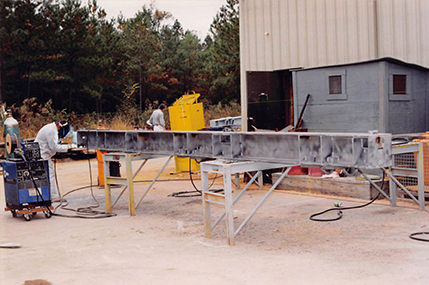

Since moving to North Carolina, Tandemloc has been able to increase manufacturing capabilities. It took several years before we were able to bring all our manufacturing under one roof. Welding was done outside with the larger products that couldn't fit inside the building and our sandblasting and painting were always done outside, along with proof testing. It was difficult to maintain quality and schedules due to weather so we eventually needed to expand.

In 2001, we completed our first expansion. We added 10,000 sq ft, extending the end of the building outward. With this, we were able to increase our office space and add room for welding and machining. We actually bought our first CNC machine around this time. We installed a large indoor abrasive blast room and paint booth. We also added the capability to perform zinc thermal spray as an added feature of enhanced corrosion resistance. Not to mention that the added space gave us the needed room for manufacturing. Our product quality saw an immediate improvement and we began to see more orders.

A significant milestone for us after our first expansion was that we receiving a major order for several Q25 Container Slings. We beat our budget for production and were able to perform "CARC painting" (Chemical Agent Resistant Coating) in house.

Just a few years later, we expanded again. We saw the need to expand as sales continued to grow for below the hook lifters and military related tie downs. The expansion allowed us to bring Proof Testing indoors. We redesigned our Proof Test stand to accommodate larger lifters with a greater capacity. We even added a camera system to record all tests with a time stamp for even further assurance.

.jpg)

To better serve our customers, we needed to put a greater emphasis on our in stock program. This eventually increased our need for more floor space and we expanded once again. We were able to secure a lot around the corner from our main building to build space for our finished inventory, raw materials and space to house and ship finished goods. This warehouse freed up significant space in our main building for manufacturing.

In 2007, we elected to conduct annual third-party auditing of our quality program. This allowed our Quality manager to write our Quality Manual, which mirrors the ISO standard, referencing our longstanding commitment to quality, safety, and customer satisfaction at every stage of our operation.

In 2008, our founder and immense engineering design talent passed away. We eventually needed to find another engineer in addition to Mike's son Bill, who was now the lone engineer. We hired someone from the industry and were able to add to our product lines of below the hook lifters.

Since then, we've added several product lines to better serve the below the hook industry. Some of these products include, Barrier Grabs, Pipe Grabs, Pallet Lifters, and Forklift attachments.

We also launched our Rapid Ready Program, allowing customers to choose their lengths, WLL, and pick points. This program enables us to ship these lift beams or spreader beams out within 5-7 business days after placing an order.

In 2009, Tandemloc was recognized and received its first SHARP (Safety & Health Achievement & Recognition Program) certification which NC Commissioner Berry presented. (N.C. Department of Labor's SHARP Recognition Program is administered through its Consultative Services Bureau of the Occupational Safety and Health Division. The SHARP Program is designed for small and mid-size employers that have established, implemented and maintained exceptional workplace safety standards.)

We received our initial ISO certification from DNV in February 2016 for the ISO 9001-2008 standard. Because we already had a well-organized system in place, we were able to achieve our ISO certifications without the help of a consultation firm.

Shortly after receiving our first certification, we began working on updating our system to achieve the ISO 9001-2015 certification, which we received in April 2018.

In 2021, several of our customers approached us looking for custom lifting equipment that would service production line manufacturing. These customers had specific requirements for their manufacturing space and the unique products they needed to lift. After our engineering team evaluated their requirements, we developed concept designs and secured order commitments for our first batch of motorized lifting equipment.

One of the products we developed was the AX17A00-00A Load Leveling Electroloc container spreader. We used a modern, PLC driven control system, rugged drivetrain components, and electrical hardware sourced from top-tier component manufacturers with solid reputations in the marine, lifting, and industrial controls industries. Combined with our decades of experience designing and manufacturing lifting equipment for intermodal and non-standard cargo handling needs, we had the perfect recipe to make our first hit a home run. We then manufactured the AX17B00-00A which is the 40 foot version of our AX17A.

We have continued to manufacture several highly customized electronic lifters, the most recent being the AZ24A00-00A Offest counterweight beam and the AZ34A00-00A Load Leveling beam.

Tandemloc maintains a volunteer safety committee of team members from the various departments who conduct monthly safety inspections and process audits. All team members participate in safety in one way or another and are committed to keeping Tandemloc safe. Everyone’s commitment shows and over the years Tandemloc has been presented with many safety awards, including Silver and Gold NCDOL annual awards, annual AWRF (Associated Wire Rope Fabricators) Safety Awards. As of 2024 Tandemloc has maintained the SHARP award for the 15th consecutive year.

Our Founder

Tandemloc's "Proof Tested" Chairman of the Board

We've been fortunate over the last many years to develop a great crew of people. John "MIKE" DiMartino, Sr. was the first and foremost employee of TANDEMLOC, INC.

A great many souls owe their livelihood to the hard work and dedication of this gentleman's life work. We can't say enough good things about the man...really. His in-depth knowledge of the ANSI / ASME, ISO, and MIL STD specifications to which we manufacture, has been a prime mover in TANDEMLOC's growth since our inception in the early 1980's. He was personally responsible for many patents. His experience goes back to the late 1950's and, at one time, he sat on the board of ISO standards.

His inspiration and spirit of innovation set the path followed by Tandemloc today. Sadly, Mike passed away in 2008 after many, many years of working every day at Tandemloc with his two sons - John Jr., former President and Bill DiMartino, former Vice-President, who have kept the TANDEMLOC ship on the course he chartered. His inspiration and spirit of innovation set the path followed by Tandemloc today.

Tandemloc's founder, John 'Mike' DiMartino